What’s the first thing you do when you start a new puzzle? You look at the front of the box, so you have an idea of the entire picture, then you start to lay out the pieces and look at everything. You study colors, shapes and edges. The same thing happens when you are presented with an engine failure case. You build the puzzle by laying out all the parts, organize the facts, think logically through them, document your findings and see how the pieces fit.

What’s the first thing you do when you start a new puzzle? You look at the front of the box, so you have an idea of the entire picture, then you start to lay out the pieces and look at everything. You study colors, shapes and edges. The same thing happens when you are presented with an engine failure case. You build the puzzle by laying out all the parts, organize the facts, think logically through them, document your findings and see how the pieces fit.

Attention to detail is a key factor in engine failure analysis and a hands-on approach will often find the root cause

What’s the matter with this picture? Hint: There are four visible clues. To make this more interesting the damage on the fractured surfaces of the rod are not part of the equation.

.

.

There is an ugly sinking feeling when a shop owner or technician sees an engine they had just finished coming back in the yard on a tow truck. What could have happened so quickly? The roar cause of this Cummins ISX failure may surprise you and it is one that rebuilders and parts departments need to be aware of.

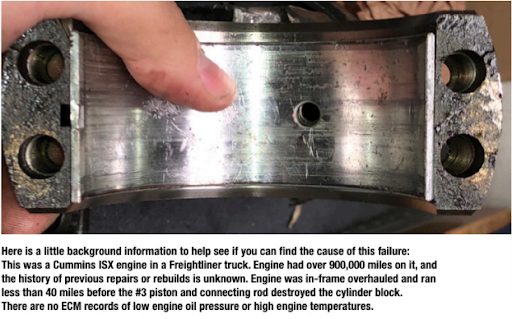

Here is a little background information to help see if you can find the cause of this failure:

Kudos to those of you that have figured it out already but let the rest of us keep going.

Kudos to those of you that have figured it out already but let the rest of us keep going.

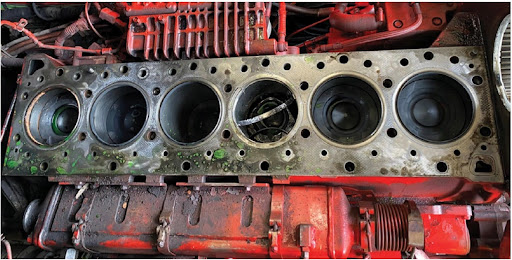

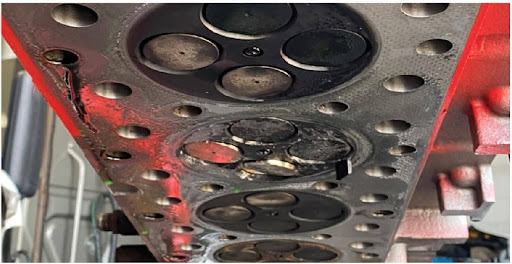

Looking at the bigger picture, removing the cylinder head found the #3 cylinders were destroyed and the cylinder block was cracked. Since there was less than 40 miles on the engine, the question remains whether the piston or liner was defective or out of specifications?

Upon closer look, the cylinder head was damaged, but all of the valves were intact. So dropping a valve was not the problem.

There was a piece of the APR ring jammed into the head. Did the APR ring  fail? If you skip ahead to the conclusion of this article you forfeit any remaining kudos.

fail? If you skip ahead to the conclusion of this article you forfeit any remaining kudos.

The entire ring carrier of the piston crown had broken off. There was heavy impact damage. The piston and rod were still attached to the crankshaft.

A 20-ton press was needed to get the piston pin out of the connecting rod.

The pin and rod bushing welded themselves together.

The primary damage was near the center of the pin and secondary damage near the ends of the pin and to the pin bosses of the piston.

The bushing in the rod had spun and was blocking the oil supply.  There was heavy adhesive damage.

There was heavy adhesive damage.

The rotation of the bushing caused it to contact the inside of the piston body.

The piston still articulates on the pin, but the pin will not move. Was that evidence of a defective piston pin, piston or reuse of a bad connecting rod? No, the puzzle has not been solved.

Back to the beginning photo, whenever you see damage to an engine bearing it is a good idea to look at all the other bearings to see what clues they may provide.

Back to the beginning photo, whenever you see damage to an engine bearing it is a good idea to look at all the other bearings to see what clues they may provide.

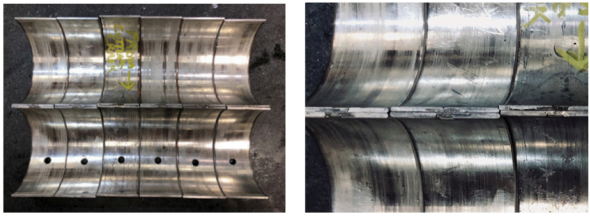

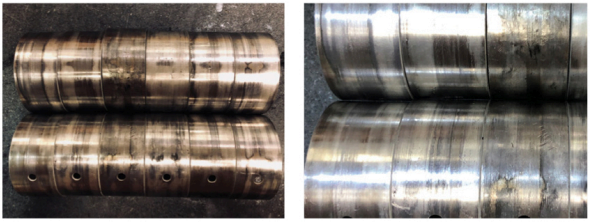

Pictured right are all six of the connecting rod bearings. The #3 bearing was from the failed cylinder. Do you see anything odd in these photos?

There are two major details they all have in common.

Did you find them?’ If not, take a look at the close-up photos (far right) and I think you will see what I have been leading up to. No cheating, we are almost to the end.

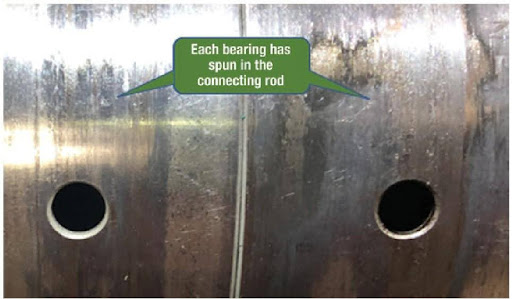

The abnormality that each of the connecting rod bearings had in common was the alignment tabs were gone and each bearing had spun in the connecting rod. This damage was not due to lack of lubrication or lack of torque of the rod bolts.

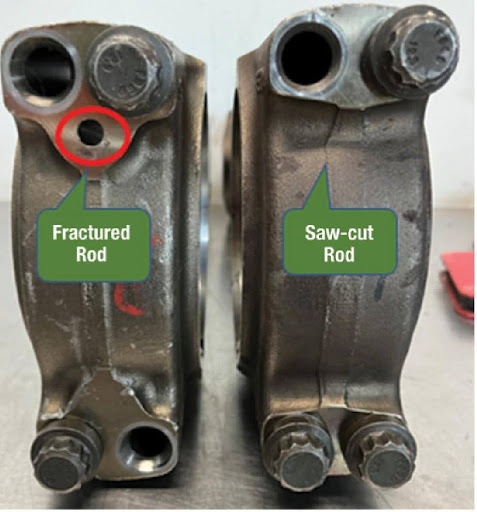

The problem is the design of the connecting rods do not match the design of these rod bearings. There are two different types of connecting rods used in ISX engines, “saw cur” and “fractured”. These terms describe the mating surfaces between the connecting rod and rod cap. “Saw cut” rods have been used for years, and “fractured” rods are the newer technology (released in 2012). Cummins allows for these rod types to be mixed in an engine, and if a rod has been replaced all the connecting rods may no longer be the same design. You can have any combination within the six rods. Matching the correct connecting rod bearing to the correct rod is critical.

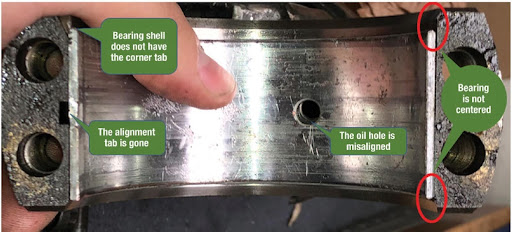

Where the real problem comes in is if someone is not paying attention to the details. Did you find the four clues in the beginning photo?

This cut rod bearing was installed in a fractured rod! The free length of the saw cut bearing allows just enough tension to hold itself in a fractured rod during assembly, and that is the root cause of this failure. A very expensive oversight.

A fractured connecting rod has a 0.032″ larger bore for the rod bearing than a saw~cut rod.

That added clearance allowed all the bearings to rotate in these connecting rods without seizing. Operating forces flatten the alignment tabs, and the rotation blocked the oil supply to the rod bushing (small end) and pin.

Fractured rods and bearings have an alignment tab, but also a folded corner. Since a saw cut rod does not have the corner relief a fracture rod bearing cannot be installed in a saw cut rod.

Unconvinced? Are you wondering “how can a piston and rod that are still connected to the crankshaft ventilate the cylinder block?” The answer lies in the design of the cylinder block and liners. ISX engines use a “mid-stop” line meaning the liner is held at the top and mid-way down on the liner. This design leaves the lower section of the liner unsupported by the cylinder block.

To recap what we know so far in this investigation:

The restriction in free movement caused by the bushing rotation, the lack of oil and the seizure of the pin caused excessive side loading of the piston against the liner. The unsupported lower section of the mid-stop cast iron liner cannot withstand the side loading force at the bottom of the piston stroke breaking the liner.

Without the liner to guide the piston, the piston rocks over and catches underneath the lower counter bore of the cylinder block. At that point things get real sad real soon and the piston and rod destroy the cylinder block.

One last snippet of information before we bring this journey to an end. As mentioned in the beginning, there is no way to know for sure which design connecting rods and bearings you will need until the engine is disassembled. Once you can see the bottom of the connecting rods there is a way to tell them apart. The fractured rods have a hole in the cap that the saw-cut rod does not have.

That brings us to the end of this journey. The hard part is finding the right pieces and then the puzzle starts to come together completing the picture. Sadly, this engine also wound up in a box like a puzzle.■

Steve Scott joined the service department at lPD in 1982, working with parts, service and sales for a variety of equipment, diesel, and natural gas engines. Since 2004, he has been the director of product development and technical support for lPD. For more information, email sscott@ipdparts.com.

If you’re an existing customer and already have a login, click here to find IPD quality parts.

If you would like to find an IPD distributor or become an IPD distributor, please fill out our form.