With heavy duty industrial engines, the engine’s owner or repair shop is often faced with the critical decisions to reuse, rebuild or replace cylinder heads and cylinder head components. The individual components in the cylinder head are not to be overlooked. Beyond the machine work that may be required to bring the cylinder head casting back into reusable condition, several of the other components in the cylinder head may also be reusable. If you intend to reuse them, understanding the technical requirements of these components is necessary for qualifying them. Many of the OEMs publish “reusability guides” to help determine if these parts can

With heavy duty industrial engines, the engine’s owner or repair shop is often faced with the critical decisions to reuse, rebuild or replace cylinder heads and cylinder head components. The individual components in the cylinder head are not to be overlooked. Beyond the machine work that may be required to bring the cylinder head casting back into reusable condition, several of the other components in the cylinder head may also be reusable. If you intend to reuse them, understanding the technical requirements of these components is necessary for qualifying them. Many of the OEMs publish “reusability guides” to help determine if these parts can

be reused. However,  “can be” and “should be” are two different arguments when discussing repairs. Some OEM guidelines are detailed explaining visible and dimensional things to look for, or check. Other guidelines are so vague that they leave many questions unanswered. Knowing the engine’s history, and what the future plans are for the engine are also factors in making these decisions. If you are planning to rebuild the engine and get a full second service life from it, then the cost savings of reusing the valvetrain components may not be so appealing. The biggest cost savings in reusing cylinder head components is likely in the valves. A thorough visual inspection may save you the expense of cleaning, measuring, grinding, and checking the valves for cracks. Do not reuse valves if you see:

“can be” and “should be” are two different arguments when discussing repairs. Some OEM guidelines are detailed explaining visible and dimensional things to look for, or check. Other guidelines are so vague that they leave many questions unanswered. Knowing the engine’s history, and what the future plans are for the engine are also factors in making these decisions. If you are planning to rebuild the engine and get a full second service life from it, then the cost savings of reusing the valvetrain components may not be so appealing. The biggest cost savings in reusing cylinder head components is likely in the valves. A thorough visual inspection may save you the expense of cleaning, measuring, grinding, and checking the valves for cracks. Do not reuse valves if you see:

Discoloration high up the valve stem is a common sign that the valve has been overheated and should be rejected.

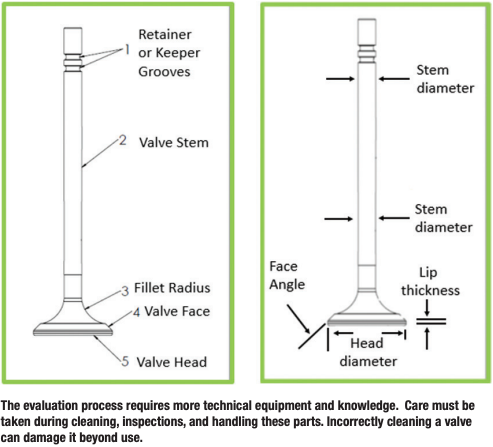

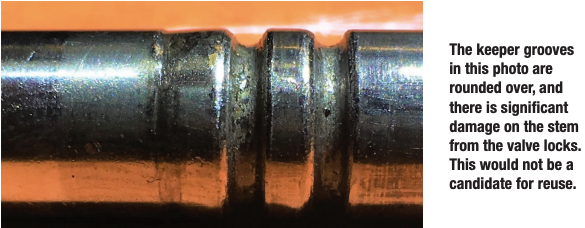

Discoloration high up the valve stem is a common sign that the valve has been overheated and should be rejected.The next steps in the evaluation process require more technical equipment and knowledge. Care must be taken during cleaning, inspections, and handling these parts. Incorrectly cleaning a valve can damage it beyond use. Some minor blemishes may be removed using a Scotch-Brite pad or polishing stone, but that leaves the interpretation of what is “minor” up to whomever is inspecting the parts. The retaining (keeper) grooves and fillet areas are high stress locations on a valve. Reusing valves that are damaged in those areas is not recommended. The keeper grooves in the photo (shown right) are rounded over, and there is significant damage on the stem from the valve locks. This would not be a candidate for reuse.

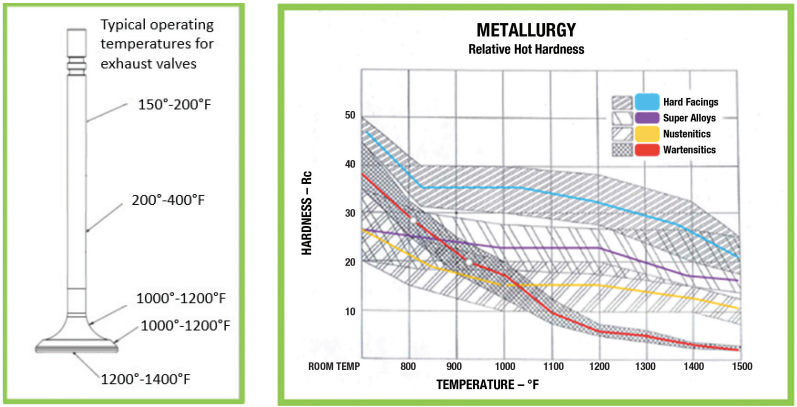

Valves are exposed to harsh conditions, and when you consider how many strokes (cycles) these parts may have already withstood over the hundreds of thousands of miles during their previous service life, it is a pretty strong argument for not reusing them. This graph shows the general operating temperature an exhaust valve can reach. As the temperatures increase, the hardness of the various materials decreases.

There are several methods available for detecting cracks in valves and the fractures shown in the following photos are obvious. No matter how small a crack is found, the valve should not be reused.

Having the correct dimensional specs to measure the valves’ stems is just as important as having the right measuring equipment. Depending on the application, the valve stem may be tapered, so where the stem is measured can affect the results. Some valves allow for the faces to be reground, but once again, that depends on the design of the valve. There may also be a minimum thickness requirement. Many valves have coatings or are hard-faced on the valve face. Regrinding the face can remove these materials, leaving the core material of the valve exposed, and the valve will not be able to survive a second service life. Verify if your application has a specification for valve recession or protrusion. Regrinding the valve face or valve insert (seat) will affect that dimension.

Testing valve springs as a rule is simple enough. Often reusability guides have spring free length and load force at a given assembled length. Springs should not be reused if there is visible wear or nicks. Another condition to look for is corrosion. Corrosion creates stress risers that can cause the spring to break.

Rotocoils and valve locks (keepers) are very rarely considered to be a reusable component. Rotocoils are a pretty unique part and are vital in prolonging the service life of the valvetrain. Rotocoils are key in causing the valves to rotate. Rotating the valves helps clean the valve face and seat (insert), and evenly distributes wear.

There are different internal designs, but they are not a component that can be disassembled, cleaned, inspected and reassembled. Testing them requires specialized equipment and turning them by hand is no indication that they will function correctly. Valve locks (keepers) are the least expensive of the valvetrain components and are not worth the risk of reusing.

Valve guides and inserts (seats) also require special equipment and tools. These are not items that most individuals can check. The concentricity between the guide and insert assure the valve will travel and seal correctly. If the guides are worn, or the inserts are not true, it’s likely the valve will fail.

The upfront saving of reusing valvetrain components may be the beginning of a costly ending. “When in doubt, don’t” (Benjamin Franklin). Seek help, AERA’s Technical Department has all of the specifications and knowledge engine builders need to help you decide to rebuild, reuse, or replace all critical engine components.

Steve Scott joined the service department at lPD in 1982, working with parts, service and sales for a variety of equipment, diesel, and natural gas engines. Since 2004, he has been the director of product development and technical support for lPD. For more information, email sscott@ipdparts.com.

If you’re an existing customer and already have a login, click here to find IPD quality parts.

If you would like to find an IPD distributor or become an IPD distributor, please fill out our form.