If you are looking at a puddle of oil on the shop floor you might say it is the crankshaft seal or oil pan gasket. Or, maybe it is one of the gaskets that cause you to keep adding coolant back into the reservoir. Rightfully, every gasket or seal is important, but the first contender may well be the piston rings, especially the compression rings. You can pick up another quart of oil, or coolant at a local parts store, but you cannot buy replacement containers of compression.

If you are looking at a puddle of oil on the shop floor you might say it is the crankshaft seal or oil pan gasket. Or, maybe it is one of the gaskets that cause you to keep adding coolant back into the reservoir. Rightfully, every gasket or seal is important, but the first contender may well be the piston rings, especially the compression rings. You can pick up another quart of oil, or coolant at a local parts store, but you cannot buy replacement containers of compression.

How many miles are on your rings? Most owners/operators can tell you the number of miles or hours on their trucks or pieces of equipment. They can likely do the same for what is on the tires, oil, and other service parts. For example, a C15 Caterpillar engine with a 6.8″ stroke running at 1500 RPM and traveling 65 MPH for one hour obviously has traveled 65 miles. But the piston rings have traveled up and down the cylinder walls a little over 19 miles in less than 7″ increments. And, they’ve changed direction 180,000 times (twice for each complete rotation of the engine). Pretty demanding duty they perform!

engine). Pretty demanding duty they perform!

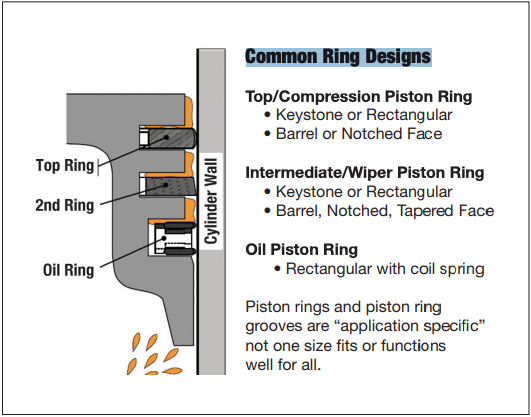

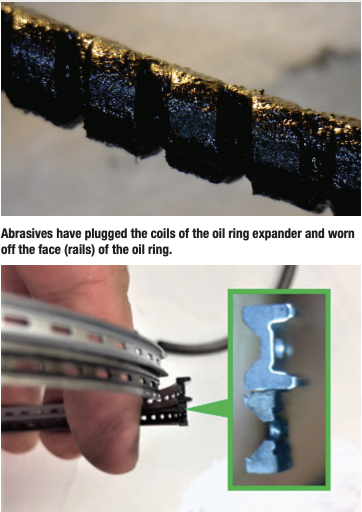

Piston rings, like many other engine components, have evolved over the years but the functionality is essentially unchanged. Most heavy-duty diesel engines use three-ring pistons. The top compression ring is responsible for sealing approximately 90% of the compression in the cylinder. It functions in the toughest of environments, being subjected to the highest thermal and mechanical loads. The intermediate rings serve a dual purpose. Their primary job is oil control, but they do contribute to sealing compression. The oil ring is the gatekeeper of the lubrication. It scrapes the excess oil from the cylinder wall, while leaving the needed amount of oil on the surface to maintain a protective oil film.

Rings are primarily thought of for sealing compression and controlling oil consumption, but they also transfer approximately 70% of the heat created by combustion from the piston to the cylinders walls to be absorbed by the cooling system. Some engines have piston cooling tubes (jets) that spray oil under the bottom of the pistons to help cool them.

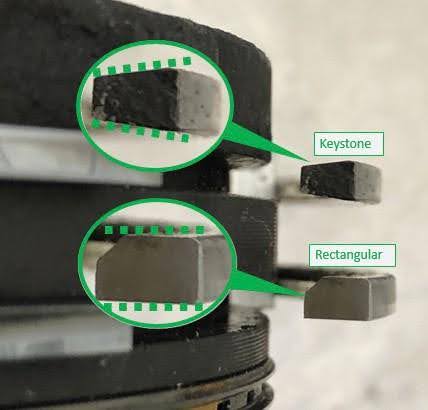

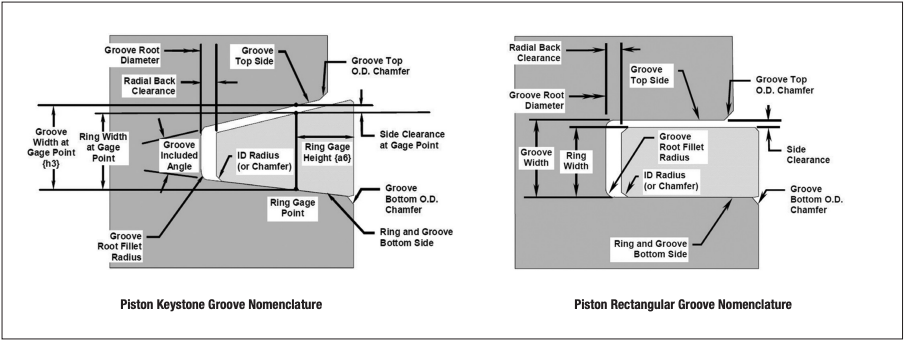

The two basic ring designs are keystone or rectangular. Keystone rings have tapered sides. During operation, this design creates a wedge effect allowing the ring to expand and retract in the ring land of the piston. This helps to reduce wear and ring sticking. The rectangular rings have a simple rectangular profile designed to maintain

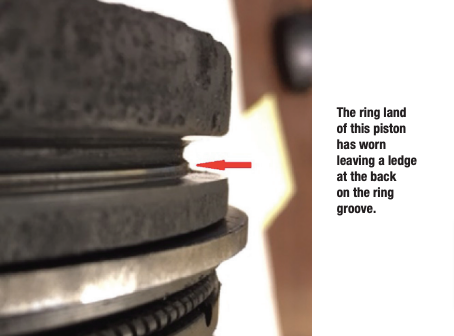

The two basic ring designs are keystone or rectangular. Keystone rings have tapered sides. During operation, this design creates a wedge effect allowing the ring to expand and retract in the ring land of the piston. This helps to reduce wear and ring sticking. The rectangular rings have a simple rectangular profile designed to maintain  constant pressure to the cylinder wall. This design has its benefits but can be more prone to sticking or wear.

constant pressure to the cylinder wall. This design has its benefits but can be more prone to sticking or wear.

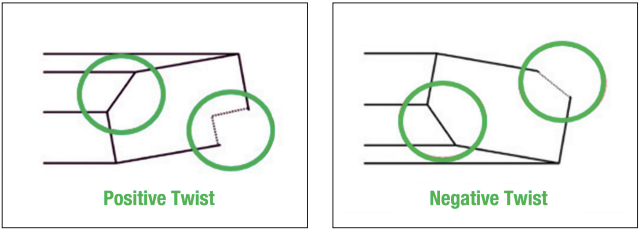

Ring designs may also incorporate notches or bevels on the inside or outside corners. Machining the upper inside or lower outside edges of the ring creates a positive twist. Doing the opposite by machining the lower inside or upper outside edges will cause a negative twist in the ring during operation.

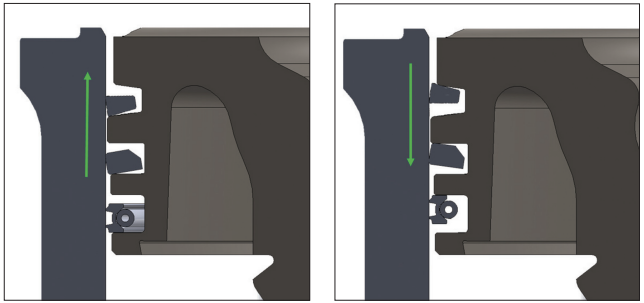

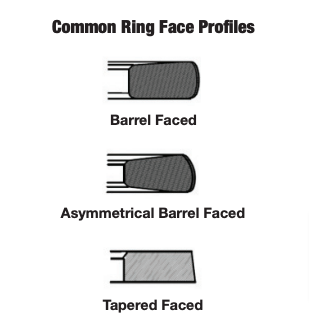

A more subtle and hard to see feature are the various designs of the ring face. The ring face is the outer edge of the ring that contacts the cylinder wall.

A more subtle and hard to see feature are the various designs of the ring face. The ring face is the outer edge of the ring that contacts the cylinder wall.

Pistons do not travel perfectly straight inside the cylinders. The operating forces and clearances allow them to rock side to side, and as shown in the illustrations on this page, rings do not stay in the same positions. They twist and move in the ring lands of the piston. To compensate for this, the engineering and geometry that goes into designing the cylinder components (liners, pistons, and rings) are far more detailed than what can be presented in this short article.

In addition to the basic designs, there are multiple different materials, coatings, and manufacturing processes used in diesel engines. There is not a “one design fits all” solution. The pistons, liners and rings must work in concert to seal the compression in the cylinder, control oil consumption, and transfer heat. The face profile, clearances, notches, materials, coatings, degree of angles and the wall finish (hone) of the cylinder walls all function together to maintain a positive seal of compression and control oil consumption. After the initial break-in procedure, which is critical on a freshly rebuilt engine, it is essential for an ongoing maintenance program to get good service life from these components. You may have heard the terms that an engine is:

In addition to the basic designs, there are multiple different materials, coatings, and manufacturing processes used in diesel engines. There is not a “one design fits all” solution. The pistons, liners and rings must work in concert to seal the compression in the cylinder, control oil consumption, and transfer heat. The face profile, clearances, notches, materials, coatings, degree of angles and the wall finish (hone) of the cylinder walls all function together to maintain a positive seal of compression and control oil consumption. After the initial break-in procedure, which is critical on a freshly rebuilt engine, it is essential for an ongoing maintenance program to get good service life from these components. You may have heard the terms that an engine is:

These complaints are commonly due to damaged rings, pistons and cylinder walls. Breathing dirty air, running dirty oil and carbon deposits are horrendous for these parts. Trapped debris can be extremely abrasive.

Piston rings are a metal seal designed to perform important tasks—sealing compression and controlling oil consumption.

Piston rings are a metal seal designed to perform important tasks—sealing compression and controlling oil consumption.

Depending on the application and engine, stopping that leaking oil pan gasket from continuing to leave a puddle of oil is fairly inexpensive — roughly three hours labor and a few parts. Replacing a rear crankshaft seal is more expensive, roughly 14 hours labor, the cost of the seal and a few other items. Replacing rings is more of a commitment, requiring somewhere around 40 hours labor. Depending on the damage it could be thousands of dollars in parts. How well you take care of the rings will determine how many miles or hours they will last. Regular routine maintenance can greatly extend the life of not only the rings but other critical engine components.■

Steve Scott joined the service department at lPD in 1982, working with parts, service and sales for a variety of equipment, diesel, and natural gas engines. Since 2004, he has been the director of product development and technical support for lPD. For more information, email sscott@ipdparts.com.

If you’re an existing customer and already have a login, click here to find IPD quality parts.

If you would like to find an IPD distributor or become an IPD distributor, please fill out our form.