You’d be surprised how often we get this question: “Am I measuring my liner protrusion wrong?” And honestly, it happens more than you’d think, especially when raised edge liners are involved.

This article breaks down exactly how liner protrusion should be measured when using IPD’s raised edge liners. What happens if you get it wrong, and why this tiny measurement is important in engine performance.

What Is Liner Protrusion, and Why Does It Matter?

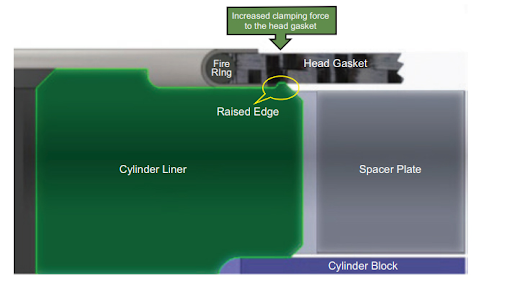

Liner protrusion is the measurement of how far the top edge of your cylinder liner sticks out above the deck surface (usually above the spacer plate). This distance sets the clamping force on your head gasket too little, and combustion leaks past. Too much and you risk damaging the fire ring or distorting the gasket.

It’s a delicate balance. The spec is tight:

- 0.06 to 0.18 mm (0.0024 to 0.0071 inch) liner projection

- Max Variation in Each Liner: 0.050 mm (0.0020 inch)

- Max Average Variation between Adjacent Liners: 0.08mm (0.0031 inch)

- Max Variation Between All Six Liners: 0.100mm (0.0040 inch)

And when you throw a raised edge into the mix, the measurement is a bit trickier but not impossible.

The Most Common Mistake: Measuring Off the Ridge

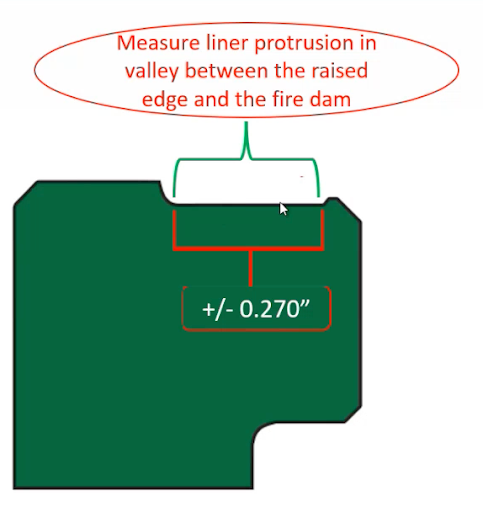

Let’s say your sled gauge shows 0.012″ too much protrusion. You’re probably measuring off the top of the raised edge (the ridge), not the actual sealing surface.

That ridge stands about 0.012″ proud, so it’s no coincidence that we hear this exact number all the time. If your gauge slides off the spacer plate and lands on that raised edge, you’re setting yourself up for an inaccurate reading.

Reminder: Do not measure from the top of the raised edge.

The Right Way to Measure Liner Protrusion on Raised Edge Liners

Here’s what you should do instead:

- Use a sled gauge (or micrometer) with a tip that’s smaller than 0.270″. This ensures you can fit into the valley.

- Lift the gauge over the ridge and lower it into the valley between the raised edge and the fire dam.

- Take your readings from that flat section inside the liner top.

This is the surface that actually mates with the fire ring and determines gasket crush.

If you skip this and measure off the ridge, you’re not only over-protruding the measurement, you might also misdiagnose a good liner as bad.

Why Raised Edge Liners Exist (and What They Don’t Do)

The Raised Edge Liner is an IPD innovation, designed specifically for Caterpillar 3400 and C15 series (5.4” bore) engines. This upgraded liner features a small raised edge (ridge) on the outer top surface of the liner flange, which embeds into the graphite material of the head gasket. The result? Increased clamping force on the gasket and provides greater support around the fire ring assembly of the gasket.

The raised edge design is part of IPD’s ongoing commitment to provide the strongest, most durable options for your Caterpillar engines. And here’s the best part: this liner can be upgraded into any “CS” engine kit at no additional cost

However, it’s important to note that the raised edge liner is not recommended for use with modified cylinder heads, such as those with secondary fire wire grooves. There are no consistent specs for the groove diameter or depth, and those modifications may interfere with the raised edge profile.

What the raised edge liner doesn’t change:

- Liner protrusion spec

- Head bolt torque values

- Torque sequence

- The head gasket itself

You can drop a raised edge liner right in place of a standard one without any changes to your installation procedure.

A Word on Those Fiber Washers

Sometimes customers ask about the soft washers included with raised edge liners. Here’s the deal:

- When torquing the liner down to measure protrusion, the washer allows the ridge to bite in without damaging it.

- If you used a steel washer instead, it could crush or deform the ridge, not bad, but not ideal.

So yes, that washer is important. It protects your liner while giving you a true reading. Make sure to follow the latest OE installation instructions by using the protective washers to ensure the flange is not damaged when checking the liner projection (protrusion).

Do This, Not That

Yes, Do This

- Measure in the valley between the raised edge and the fire dam

- Use a sled gauge with a tip smaller than 0.270″

- Follow the original protrusion spec

- Use soft washers under liners

Not That

- Measure on top of the ridge

- Let your gauge rest on the outer ring

- Add 0.012″ because of the ridge

- Use steel washers

Still Got Questions? Reach out To Us!

Liner protrusion may seem like a small detail, but it’s important for head gasket life, compression sealing, and engine performance.

At IPD, we design and machine our components to tight tolerances so you don’t have to guess. We also provide support, documentation, and advice to help rebuilders and distributors. Need help? Contact us today!