When Caterpillar launched the C7 engine in 2003, it wasn’t just another mid-range diesel; it was a major step toward cleaner, electronically controlled engines. Designed to meet new EPA standards while delivering dependable horsepower, the C7 earned its place in fleets across North America and beyond. Today, it continues to be rebuilt, supported, and trusted by operators in a wide range of industries.

This article takes a deep dive into the C7’s origin story, technical evolution, key strengths, and why so many machines still rely on it today, with support from aftermarket parts providers like IPD.

For more information about IPD products and parts for Caterpillar C7, click here.

Why the C7 Was Created: A Clean Start for Caterpillar

The Caterpillar C7 replaced the popular 3126, bringing improved performance, tighter emissions control, and a refined fuel injection system. By the early 2000s, emissions regulations were becoming more aggressive. Caterpillar needed an engine that could power medium-duty vehicles without compromising fuel efficiency or durability.

The result was the C7, built on the foundation of the 3126 but reengineered for lower emissions, higher precision, and better drivability. It was Caterpillar’s flagship answer to the EPA 2004 regulations and stayed in production until around 2009.

Core Specs and Technical Features

The C7 was built to serve demanding vocational and municipal needs while meeting emissions requirements. Its specs reflect a balance of size, power, and reliability:

- Displacement: 7.2 liters

- Configuration: Mid-range six-cylinder engine

- Horsepower Range: ~190–360 hp

- Torque: Up to 860 lb-ft

- Fuel System: HEUI (Hydraulically actuated Electronic Unit Injection)

- Turbocharged: Yes, with wastegate

- Dry Weight: ~1,425 lbs

- Cooling System: Water-cooled

The engine’s balance of power and efficiency made it ideal for stop-and-go driving, highway hauling, and off-road use.

Top Applications: Where the C7 Earned Its Reputation

One of the C7’s biggest advantages was its versatility. It powered a wide variety of platforms, including:

- Medium-duty trucks: Freightliner M2, International 4000 Series, and Sterling trucks that required dependable mid-range torque and quick throttle response for local and regional hauling.

- Municipal and vocational fleets: Dump trucks, refuse trucks, sweepers, and snow plows, where consistent low-end power, fuel efficiency, and uptime were essential for daily operations.

- Generators and marine auxiliary power: The C7’s adaptability made it ideal for stationary equipment and light marine duty, where long hours of operation demanded proven endurance.

HEUI Fuel System: Performance and Precision

One of the defining features of the C7 was its HEUI system, carried over from the 3126 but further refined. HEUI allowed the engine to regulate fuel pressure independently of engine speed, improving cold-start performance and emissions control.

Benefits of HEUI:

- Precise fuel delivery

- Better throttle response

- Improved cold-weather starting

- Lower particulate emissions (pre-DPF era)

Key Considerations:

HEUI systems rely heavily on clean oil to maintain injector function. Poor maintenance can lead to injector leaks or high-pressure oil system failures. For rebuilders and techs, attention to oil cleanliness, O-rings, and injection pump health is critical during overhaul.

Emissions Compliance and DPF Introduction

The C7 initially launched without a diesel particulate filter (DPF), making early models simpler and more service-friendly. However, when EPA 2007 regulations took effect, Caterpillar added a DPF and exhaust gas recirculation (EGR) system to the C7.

2003–2006 Models:

- Pre-DPF

- HEUI injection

- Lower complexity, preferred by rebuilders

2007–2009 Models:

- Equipped with DPF and EGR

- Required ULSD fuel

- More electronics and sensors, adding service considerations

While emissions upgrades were necessary, they added complexity to the platform, especially for rebuilds and diagnostics. Still, these changes allowed the C7 to remain compliant while delivering solid output and drivability.

Known C7 Issues (and Practical Fixes)

No engine is perfect, and the C7 had a few known problem areas. Fortunately, many are well understood and manageable with quality parts and proactive care.

Common C7 Weak Points:

- Injector seal failures: Often caused by oil contamination

- Turbocharger wear: Especially in high-mileage vocational fleets

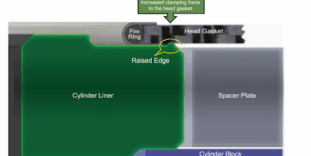

- Cracked cylinder heads: Mostly in later DPF-equipped units

- DPF clogging: In post-2007 models with long idle times

- High-pressure oil system leaks: Usually from injector O-rings or HPOP seals

These issues can typically be resolved during a rebuild. IPD offers OE-quality components that help mitigate many of these failure points, extending engine life for C7 owners.

Why Rebuilders Still Trust the Caterpillar C7

Even though Caterpillar exited the on-highway market in 2010, the C7 remains popular among rebuilders for several reasons:

- Overbuilt bottom end: Strong crankshaft and block

- Parts availability: Especially through IPD’s aftermarket support

- Mechanical simplicity: Particularly in pre-2007 models

- Wide application base: Still actively used across North America

Rebuilders looking for a solid, reliable platform continue to invest in the C7 for medium-duty vocational trucks and equipment.

The End of Production and Continued Demand

Caterpillar discontinued the C7 in 2009 as emissions standards pushed diesel manufacturers toward SCR (Selective Catalytic Reduction) and more advanced ECM systems. Instead of adapting the C7 to SCR, Caterpillar exited the highway engine market and refocused on off-road, marine, and industrial engines.

Despite that, demand for the C7 has remained steady, especially for in-frame rebuilds. It’s common to find fleets with multiple C7-powered units still on the road and still profitable.

The C7’s Legacy: Still Powering Fleets Today

The Caterpillar C7 helped bridge the gap between mechanical engines and modern emissions-era diesels. It brought electronic fuel control and cleaner emissions without sacrificing Caterpillar’s reputation for rugged performance.

Fleet operators, municipalities, and rebuild shops continue to turn to the C7 for reliable, mid-range diesel performance. With the right parts and support, many C7s are running well beyond 500,000 miles or 20,000 hours.

Extend Your C7’s Life with IPD Parts

IPD proudly supports the Caterpillar C7 platform with a full line of high-performance aftermarket components. From pistons and rings to gaskets, bearings, and full in-frame rebuild kits, our parts are designed to meet or exceed OEM specifications.

Whether you’re maintaining a city fleet, rebuilding for resale, or extending the life of a vocational truck, IPD parts are trusted by professionals across the globe. Contact us today to learn more about our C7 offerings and how we can support your operation.