Ask any diesel tech or fleet manager about the most dependable mid-range engines, and the Caterpillar C3306 is bound to make the list. For decades, this engine has powered everything from construction equipment to marine vessels, proving itself in some of the harshest environments imaginable. Known for its mechanical simplicity and rugged design, the C3306 is still going strong after more than 50 years. In this IPD article, we’ll look at where the C3306 came from, what made it such a trusted choice across industries, and why rebuilders continue to rely on it today.

For more information about IPD products and parts for Caterpillar C3306, click here.

The Origins of the Caterpillar C3306

The story of the C3306 starts with the D330 engine, Caterpillar’s workhorse from the 1960s. As technology evolved, so did the demands of the industries Caterpillar served. The D330 offered solid reliability, but as equipment got bigger and emissions regulations tightened, Caterpillar needed to adapt.

Enter the C3306. Introduced in the 1970s, this inline 6-cylinder diesel engine brought enhanced displacement, better combustion efficiency, and tougher design features. While it kept the mechanical simplicity of its predecessor, the C3306 brought improved durability, smoother power output, and greater adaptability.

Key Features That Defined the C3306

The C3306 became a favorite among operators and fleet managers thanks to a set of well-rounded features. It wasn’t overengineered, but it got the job done and kept doing it for years.

Here are the specs that made the C3306 a standout engine (depending on configuration):

- Displacement: ~10.5 liters (638 cubic inches)

- Configuration: Inline 6-cylinder, 4-stroke cycle

- Horsepower: Commonly in the range of ~125 to ~300 hp

- Torque: Frequently rated around ~500 to ~860 lb‑ft

- Fuel System: Mechanical direct injection

- Aspiration: Available in both naturally aspirated and turbocharged versions

- Cooling: Water-cooled system

- Governing: Available with fixed or variable speed governors

The simplicity of the mechanical injection system made it ideal for remote job sites and fleets that needed easy serviceability.

C3306 Applications Across Industries

The C3306 wasn’t just a construction engine. It found a home in dozens of heavy-duty applications thanks to its dependable performance and ease of maintenance.

Top industries and equipment using the C3306 include:

- Power Generation: Widely used in generator sets for both standby and continuous power.

- Marine: Propulsion and auxiliary power in tugboats, trawlers, and small cargo vessels.

- Oil and Gas: Skid-mounted pump units, compressors, and portable equipment.

- Construction: Air compressors, drilling rigs, compactors, and more.

- Agriculture: Irrigation pump systems and stationary power units.

Its ability to thrive in harsh environments with minimal maintenance helped establish the C3306 as a globally trusted engine.

C3306 Engine Variants

Over the years, Caterpillar has produced several variations of the C3306 engine to suit different markets and equipment needs. While the core engine architecture remained consistent, each variant offered slight differences in output, fuel delivery, and configuration to meet the demands of different industries and operating environments.

Common Caterpillar C3306 variants include:

- C3306NA: Naturally aspirated version with a simpler design and fewer components. Ideal for fixed or low-demand applications where simplicity and reliability are the top priority.

- C3306T: Turbocharged version offering more horsepower, improved torque characteristics, and better performance in high-altitude or heavy-duty applications such as compressors and drilling rigs.

- C3306DITA: Turbocharged and aftercooled, this version provides enhanced power and thermal efficiency. It was widely used in marine applications and high-demand industrial settings where controlled temperatures and consistent output were critical.

- C3306B: An updated variant with emissions improvements, better fuel economy, and more robust internal components. The C3306B helped bridge the gap as Caterpillar transitioned toward newer engine platforms and EPA standards.

Why the C3306 Became a Rebuilder’s Favorite

Engine rebuilders and fleet operators continue to support the C3306 long after its prime production years. Why? Because it was built to last. The engine block, crankshaft, and other major components were overengineered with longevity in mind.

Rebuilders favor the C3306 for several reasons:

- Serviceability: The mechanical fuel system and straightforward design allow rebuilds without specialized tools.

- Parts Availability: With a long production run and global use, aftermarket parts are widely available.

- Durability: These engines were designed to run for 20,000+ hours with proper maintenance.

- Simplicity: No ECM or complex electronics means fewer failure points in the field.

- Low Total Cost of Ownership: Fewer electronic parts, long service intervals, and strong parts availability combine to make the C3306 cost-effective to maintain.

- Proven Track Record: From drilling rigs to generators, the C3306 has proven itself in the harshest conditions around the world.

IPD continues to support the C3306 with premium aftermarket components, such as pistons, liners, bearings, gaskets, and full rebuild kits, trusted by distributors and rebuilders around the world. Whether you’re overhauling an engine in the shop or in the field, IPD Parts help extend the life of these legendary powerplants.

Common Issues and How to Prevent Them

No engine is without its quirks. While the C3306 has a strong track record, it’s still important to be aware of its common issues and how to handle them.

Top issues reported with C3306 engines:

- Fuel Injection Problems: Worn injectors can cause poor combustion and excess smoke.

- Turbocharger Wear (T Models): Heavy-duty use can shorten the life of the turbo.

- Oil Leaks: Common around valve covers and front timing gear seals.

- Cooling System Failures: Clogged radiators or failed water pumps can lead to overheating.

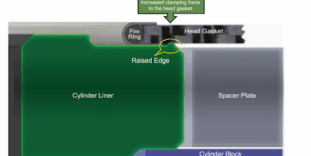

- Worn Cylinder Liners: Especially in high-hour engines without proper coolant additives.

Preventative tips:

- Stick to a regular maintenance schedule.

- Use high-quality fuel and oil filters.

- Monitor coolant chemistry to avoid liner pitting.

- Replace seals and gaskets at signs of wear.

- Use OE-quality parts during rebuilds.

The C3306 Legacy Lives On

Although the C3306 is no longer in active production, it remains in use around the world, from U.S. generator yards to marine vessels in Asia and oilfields in South America. Its tough construction, easy maintenance, and long service life make it a smart investment for operators who depend on reliable diesel power.

Whether you’re rebuilding a C3306 for industrial use or keeping legacy equipment running, there’s still strong support from aftermarket suppliers like IPD.

Need C3306 Engine Parts? IPD Has You Covered

At IPD, we understand the value of keeping proven engines like the Caterpillar C3306 running strong. We offer a full range of precision-engineered parts for overhauls, rebuilds, and maintenance. Our components meet or exceed OEM specifications and are trusted by rebuilders and fleet operators worldwide.

From cylinder kits to full gasket sets, we supply the quality you expect and the durability your operation depends on. Ready to rebuild or maintain your C3306? Contact IPD today.