The Caterpillar C3116 engine might not make headlines like newer models, but it continues to earn its place in the diesel world. Built for reliability and designed for versatility, this medium-duty diesel engine helped shape Caterpillar’s reputation in the vocational and industrial sectors.

If you manage a fleet, sell aftermarket components, or rebuild engines, the C3116 deserves a second look, not just for its history, but for the legacy it leaves behind. Let’s take a closer look at where it came from, how it performed, and why it’s still relevant today.

For more information about IPD products and parts for Caterpillar C3116, click here.

Why Caterpillar Introduced the 3116

In the late 1980s and early 1990s, Caterpillar saw a growing need for a medium-duty diesel engine that could serve a broad range of equipment. Heavy-duty platforms already had proven options like the 3406 and 3306, but something was missing in the midrange space.

The 3116 filled that gap.

Developed to support trucks, buses, industrial equipment, and marine auxiliary systems, the 3116 was Caterpillar’s first foray into smaller displacement engines designed for medium-duty use. It marked a shift in focus toward flexible, reliable engines that could serve both on-highway and off-road applications without excessive complexity.

It also laid the foundation for later models like the 3126 and C7.

Key Specs and Engine Design

The C3116 is a 6.6L inline 6-cylinder diesel engine. Depending on the configuration, it delivered between 205 and 350 horsepower and torque ratings ranging from 420 to over 700 lb-ft. For its class, those numbers were competitive, and in real-world conditions, it performed with consistency.

Key engine specs:

- Displacement: 6.6L (402 cubic inches)

- Bore x Stroke: 4.13″ x 5.0″

- Valvetrain: OHV, 4-stroke cycle

- Fuel System: Mechanical unit injection

- Turbocharging: Available in most configurations

- Cooling: Liquid-cooled with aftercooled options

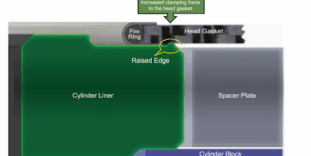

The 3116 used a cast-iron block and head with wet cylinder liners. Its forged crankshaft and connecting rods were built to withstand harsh environments, which helped boost the engine’s reputation for durability.

Where the C3116 Was Used

The C3116 earned its keep across multiple industries thanks to its durability and manageable size. Here’s a breakdown of where it saw the most action:

- Medium-duty trucks: GMC TopKick, Chevrolet Kodiak, Ford F-Series (F600–F750)

- Vocational trucks: Dump trucks, utility service trucks, bucket lifts

- Industrial applications: Stationary generators, pumps, and air compressors

- Marine: Auxiliary power and propulsion for small commercial vessels

The engine’s versatility made it a dependable option across sectors that required consistent uptime and simplified service.

Variants and Technical Evolution

The 3116 platform included both naturally aspirated and turbocharged versions. Some marine and generator versions were designed for continuous operation at high RPM, while truck versions were tuned for better low-end torque and transient response.

Over its lifecycle, Caterpillar introduced electronic variants of the 3116. These incorporated electronic control modules (ECMs) to help meet tightening emissions standards and allow for better fuel mapping and diagnostics. The transition wasn’t without challenges; early electronic models sometimes faced reliability issues, but they were necessary steps toward more modern engine platforms.

This engine eventually gave way to the Caterpillar 3126 in the mid-1990s, which improved performance, emissions handling, and diagnostics.

Strengths That Rebuilders Appreciate

Even decades later, engine builders still value the C3116 for its rebuild potential. Caterpillar designed the engine with accessibility and longevity in mind, two traits that keep these units running well beyond their intended service life.

Here’s why it continues to win with rebuilders and fleet owners:

- Straightforward Architecture: No complex emissions systems or aftertreatment

- Durable Internals: Forged components and thick castings that hold up under stress

- Parts Availability: With years of production and global usage, quality aftermarket components are widely available

- Simplicity in Service: Wet sleeves, unit injection, and accessible hardware make rebuilds manageable

- Mechanical Options: Earlier versions lack ECMs entirely, which means fewer electrical failure points

IPD continues to support the C3116 platform with OE-quality pistons, liners, ring sets, gaskets, and full rebuild kits engineered for long-lasting performance.

Common Issues and Maintenance Tips

Like any workhorse engine, the 3116 has its quirks. When neglected, some issues are more likely to surface, but most are manageable with regular service and the right parts.

Known problem areas:

- Injector Wear: Especially in high-hour or poor-fuel conditions

- Turbocharger Failure: Particularly in heavy-duty use without proper cooldown practices

- Cooling System: Dirty coolant or clogged radiators can cause overheating

- Oil Leaks: Older gaskets may seep at timing covers or valve covers

- Fuel Control Issues: In ECM-equipped versions, sensor or harness failures may cause misfiring

Maintenance best practices:

- Use high-quality oil and change it at manufacturer-recommended intervals

- Flush and refill the coolant system every 12–24 months

- Allow turbocharged engines to idle before shutdown

- Use fuel treatments to prevent injector coking

- Inspect wiring harnesses and sensor leads in electronic versions

Choosing premium parts can make the difference between another 20,000 hours and a rebuild that doesn’t last. That’s why professional rebuilders choose IPD for trusted components.

Why It Was Eventually Retired

Despite its success, the 3116 wasn’t built to meet 21st-century emissions regulations. As governments pushed for cleaner engines, Caterpillar responded with newer platforms like the 3126 and, later, the C7, which offered improved power, better diagnostics, and tighter emissions control.

By the early 2000s, the 3116 had been phased out of most on-highway applications. However, in the marine, industrial, and generator markets, it continued to find life, especially with fleets that preferred mechanical simplicity and lower long-term costs.

The C3116’s Lasting Impact

Even though production ended years ago, the 3116 remains active in fleets around the world. It helped transition Caterpillar into the medium-duty space and created a foundation that influenced a generation of engines.

Rebuilders, engine shops, and parts distributors continue to support the platform because the demand is still there. When maintained correctly or rebuilt with quality parts, these engines can log tens of thousands of additional hours in the field.

IPD and the C3116 Engine

The Caterpillar C3116 may no longer roll off the factory line, but it’s far from obsolete. It’s still powering work trucks, backup generators, and marine vessels every day.

At IPD, we understand the value of proven platforms like the C3116. That’s why we continue to offer premium, OE-quality replacement components, from pistons and cylinder liners to complete rebuild kits, all designed to keep these engines running strong.

Trust IPD for the quality, consistency, and technical support your operation demands. If you have questions about parts and products for the C3116, feel free to contact us today!