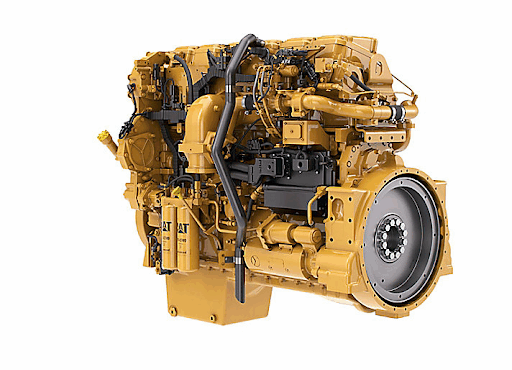

Ask any diesel mechanic or fleet operator to name an engine they trust, and chances are, the Caterpillar C15 will be one of the first they mention. Built to haul, dig, pull, and power through almost anything, the C15 wasn’t just another engine in the lineup. It was a legend in the making.

In this article, we’ll take a look at how the C15 engine came to be, how it evolved over time, and why it still shows up in trucks, generators, and rebuild shops around the world. We’ll keep it simple, straight, and packed with the kind of insight only a diesel engine deserves.

What Is the Caterpillar C15 Engine?

The Caterpillar C15 is a 15.2-liter inline six-cylinder diesel engine first introduced in 1999. It replaced the popular 3406E engine and quickly earned a reputation for being one of the most dependable engines Caterpillar ever produced.

Its job? Deliver power, torque, and durability in the toughest conditions, whether it was long-haul trucking across America or working deep in a mining pit. It didn’t just do the job, it did it without complaining.

At IPD Parts, we proudly supply high-quality replacement parts for Caterpillar engines, including the C15, to distributors and suppliers worldwide.

Why Caterpillar Created the C15?

Back in the late ’90s, the industry was facing tighter emissions regulations and higher performance demands. The 3406E had done well, but Caterpillar needed a new engine that could hit EPA targets without sacrificing power.

Enter the C15. It was Caterpillar’s answer to evolving emissions standards, and it kept the same general structure and layout as the 3406E but with refinements under the hood.

The earliest C15 engines (sometimes called “Bridge” engines) still used single turbos and traditional EUI fuel systems. But as the years rolled on, Caterpillar began to push the engine even further.

C15 Engine Specs That Made It Stand Out

- Displacement: 15.2 liters (928 cubic inches)

- Configuration: Inline 6-cylinder, 4-stroke

- Bore x Stroke: 5.4 in x 6.75 in

- Horsepower Range: 435–650 hp

- Torque: Up to 2,050 lb-ft

- Fuel System: HEUI (Hydraulically actuated Electronic Unit Injector)

- Turbocharging: Single or dual turbo (depending on the year)

- Cooling System: Water-cooled

Put simply, the C15 delivered big torque and horsepower in a package that wasn’t afraid of a heavy load. It could idle all day or hit the highway with equal ease.

The ACERT Era: A Big Change

In 2003, Caterpillar introduced ACERT technology (Advanced Combustion Emissions Reduction Technology) to help the C15 meet EPA Tier 4 emissions standards. This was a big turning point.

ACERT engines used twin turbochargers and advanced electronics to control combustion temperatures and emissions. It worked, but it also added complexity. Some mechanics loved it. Others… not so much.

Pros of the C15 ACERT:

- Lower emissions

- More refined fuel control

- Improved engine efficiency

Cons:

- More sensors and electronics to maintain

- Not as simple to repair as pre-ACERT models

Still, the C15 ACERT engines became a staple in over-the-road trucking, heavy equipment, and marine applications.

C15 Model Codes Explained

If you’ve ever rebuilt or ordered parts for a C15, you know model codes matter. Here are a few common ones:

- 6NZ: Pre-ACERT, highly respected for reliability

- MXS/BXS/NXS: ACERT engines

- SDP: Later ACERT, more emissions components

6NZ models are still some of the most sought-after C15s for rebuilds. They’re simpler, easier to work on, and known for their long lifespan.

Common Applications of the C15 Engine

The C15 was a true all-rounder. It showed up in:

- Long-haul trucks (Peterbilt, Kenworth, Freightliner)

- Mining equipment

- Construction machinery

- Marine propulsion and generators

- Industrial power systems

Its ability to handle abuse and still keep running is why many fleets still rebuild and reuse these engines today.

Common C15 Engine Problems (and Fixes)

No engine is perfect, and the C15 had a few issues worth knowing:

- Head gasket failures: Especially in high-boost applications

- Camshaft wear: Due to oil contamination or poor maintenance

- Turbocharger failure: Common in ACERT models with twin turbos

- Injector problems: Usually related to HEUI system issues

Preventative maintenance and using OE-quality parts (like those from IPD) can help extend engine life and avoid costly breakdowns.

Why the C15 Was Phased Out

By 2010, Caterpillar had exited the on-highway engine market entirely. New emissions regulations required expensive changes, and Caterpillar chose to focus on off-highway engines, marine, and industrial power instead.

That meant the end of the C15 for highway trucks. But it wasn’t the end of the engine. Variants of the C15 are still used in non-road equipment and marine applications today.

C15 vs. 3406E vs. C13 vs. C16

- 3406E: The C15’s predecessor. Very similar in design and performance. Still popular.

- C13: A smaller engine (12.5L). Good for medium-duty trucks, but with less torque.

- C16: Bigger sibling to the C15. More displacement and power, but heavier and less common.

The C15 hit the sweet spot: power, weight, and reliability all in one.

The Legacy of the Caterpillar C15 Engine

Today, the C15 is one of the most rebuilt and supported engines in the diesel world. Mechanics know it. Fleet managers trust it. And rebuilders keep it alive with the help of aftermarket parts.

IPD Parts is proud to support this legendary engine with precision-made pistons, cylinder liners, bearings, ring sets, gasket sets, and full overhaul kits. Our parts meet or exceed OEM specs and are trusted by rebuilders around the world.

The C15 Engine is Still a Legend

Even though Caterpillar no longer makes the C15 for trucks, its reputation hasn’t faded. From its early days as a workhorse to its continued use in rebuilds today, the C15 has more than earned its place in diesel engine history.

Need parts for your Caterpillar C15? IPD Parts supports distributors and rebuilders worldwide with reliable, OE-quality components built to perform. Contact us today!